Turbo Remanufacturing, Repair, Rebuild, what's the difference

Turbochargers play a crucial role in ensuring the efficiency and power of car engines. But what should you do when a turbocharger fails? Drivers often face the question: is it better to repair, rebuild, refurbish, or buy a new turbo? In this article, we will discuss in detail the differences between each type of turbo refurbishment to help you understand which option is best for your situation.

Turbocharger Remanufacturing

What distinguishes turbocharger refurbishments? Let’s start with what a refurbished turbocharger is: it’s an original damaged turbo that has been brought back to life through repair / refurbishment (remanufacturing) / reconditioning. Why do we differentiate between these three terms? The answer lies in addressing another question: why can the same turbo cost anywhere from 100 to 300 euros on the marketplace? Where does this price difference come from?

In an article on Wikipedia, the fundamental differences between repair, refurbishment, and reconditioning of components are described (link to the article).

The repair involves restoring damaged parts to a usable condition, often with minimal resource expenditure. Rebuilding, on the other hand, is a more advanced process in which key components are replaced to restore the full functionality of the device. Refurbishment involves renewing the device by replacing all moving parts with new ones, resulting in a product that is nearly factory-quality but at a lower price.

We will further explain this using the example of turbo refurbishment.

Turbo Repair

This is the cheapest method of fixing a turbo. It involves replacing or repairing individual parts of the turbo that have been damaged or destroyed. In this case, the entire turbo is disassembled for an assessment of the condition of each component. Typically, repair kits, compressor wheels, plates, and sometimes shaft&wheels are replaced. The rotating assembly is then reassembled and rebalanced. This method is the cheapest because fewer parts are used in the repair. However, it is also the least reliable method, as the final product’s quality largely depends on the technician’s experience in assembling the turbo. If any components that need repair are overlooked, or if assembly or balancing procedures are not followed, it could lead to a short lifespan for the turbocharger.

Turbo Rebuilding or Refurbishment

Turbo rebuilding involves replacing the entire core of the turbo. Most often, this includes replacing the entire center section (cartridge, rotating assembly), and possibly the variable geometry and/or valve. This method offers better longevity because new rotating elements are used. The downside is the higher repair cost. In our opinion, this is the best option in terms of quality-to-price ratio.

Rebuilding can be an ideal solution for those who are looking for a balance of quality and cost. During the rebuilding process, special attention is paid to the quality of the components used, which directly impacts the durability and reliability of the turbine after the rebuild.

"True" Turbocharger Refurbishment

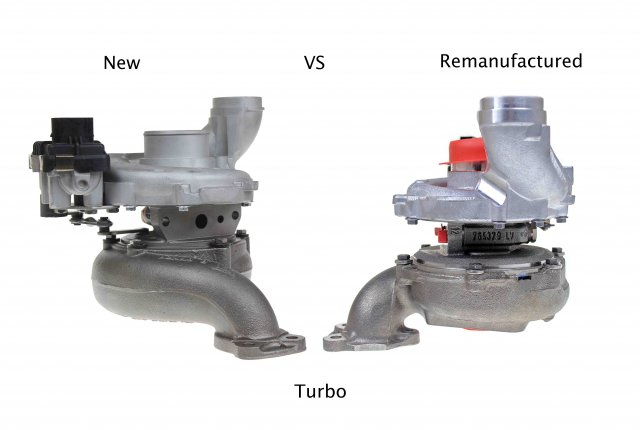

This method of turbo refurbishment involves replacing all the moving parts of the turbo with new ones. For example, in the case of a VW Passat 1.9 TDI turbo, the cartridge, variable geometry, and actuator would be replaced. Only the turbo housing and compressor housing remain.

With turbo refurbishment, you are guaranteed to receive a part in the same condition as the original turbo but at 30-40% lower cost. The effectiveness of this method is even confirmed by turbocharger manufacturers like Garrett and BorgWarner, who offer factory-refurbished turbos.

Refurbishment is the most expensive option among the renewal methods, but it is also the most comprehensive. All key components are replaced with new ones, ensuring maximum performance and reliability. For turbochargers, refurbishment is often the preferred method among professional mechanics and automotive enthusiasts who value quality and longevity.

Symptoms and Causes of a Damaged Turbocharger

Regardless of which turbo repair method you choose, it is important to know the symptoms and causes of turbo damage. This is necessary to eliminate the possibility of another malfunction. From our experience, damage to both repaired and new turbos most often occurs due to a lack of proper diagnosis and repair of the fault that caused the turbo to fail.

- Loss of engine power: A significant decrease in vehicle performance, e.g., the car doesn’t exceed 100 km/h.

- Lack of boost pressure: The car doesn’t reach above, e.g., 3,000 RPM, or doesn’t accelerate when the gas pedal is pressed.

- Exhaust smoke: Black or blue smoke during driving.

- Smoke from under the hood.

- Whistling during acceleration: Turbo whistle during acceleration.

- Increased oil consumption: Higher engine oil consumption, with the oil change light on the dashboard lighting up.

Where to Best Remanufacture Your Turbo?

If you are looking for a place to refurbish your turbo and solve your turbo-related issues, we warmly invite you to contact us. At Wiatreo.pl, we have one simple principle during turbo refurbishment – to maximize quality, longevity, and reliability, we use turbo core replacements and other components. We use parts from the best manufacturers in the market: Turbocentras UAB, E&E Turbo, and Melett.

This way, you can be confident that your turbine will be restored to factory condition and will serve you for a long time.