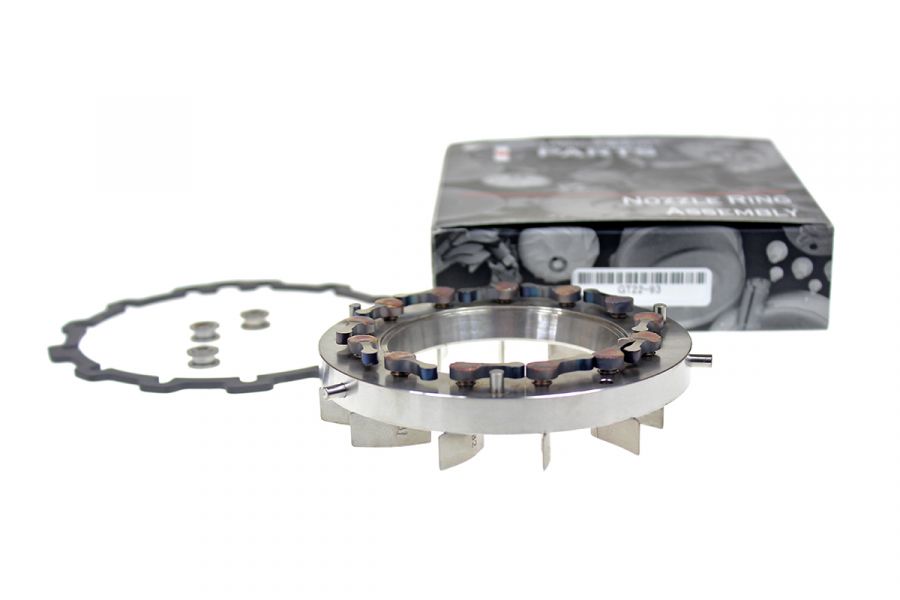

Nozzle rings assembly

Nozzle ring for AL0059 Mercedes 2.1 CDI 100/120/125kW 2012 A6510900786

Nozzle ring for 18589700001 BMW Series 5 540d (G30/G31) 3.0L 235kW

Nozzle ring assy 580243824 Peugeot Boxer 2.3 BlueHDI MULTIJET 128kW 2019

Nozzle ring assy 46351871 Fiat 1.6L M-jet 84kW 2020- 46352758 RHV3-C43T36

Nozzle ring for 05L253019F VW Passat 2.0 TDI DSRB 110kW FWD 2019-

Nozzle ring for MERCEDES W213 E220D 2.0L OM654920 120kW A6540902400

Nozzle ring assy. 173900 1842337C91

Nozzle ring 11559700001 320/06177 JCB Construction 4.8L 444/448

Nozzle ring 751851 Ford Focus I 1.8 TDCi TDCi

Nozzle ring assy 282312U000 843814-0008 Hyundai i40 1.6L CRDi 98kW 2018-

Nozzle ring KK2Q-6K682-BA 850229 Ford Transit 2.0 ECOBLUE 95kW 2018-

Nozzle ring BW-06-0029 for 53039700394 Citroen C4 2.0L BlueHDI 100 kW

Nozzle ring 752610 FORD TRANSIT 350 2.4 TDCI

Nozzle ring 54409700002 SEAT LEON 2.0 TDI CFHC

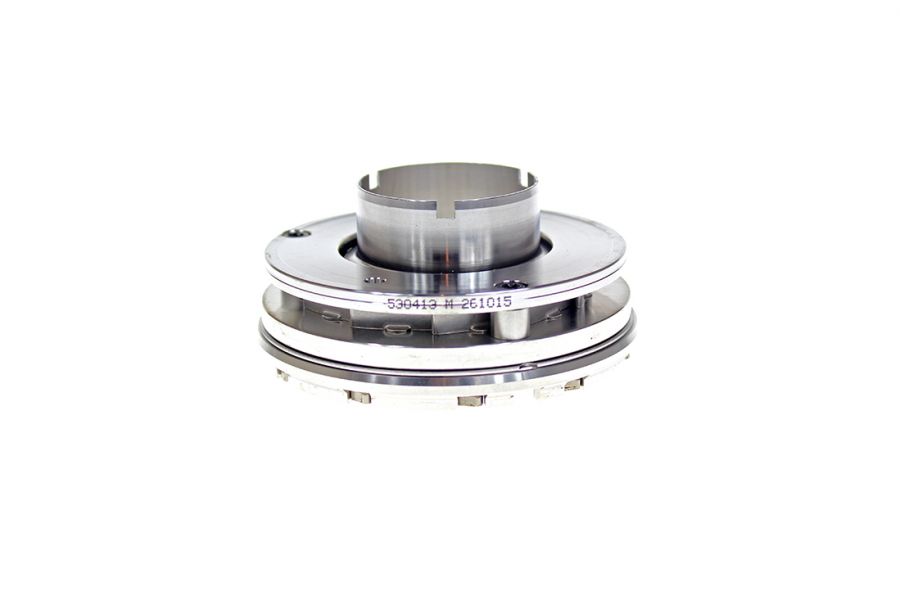

Turbo variable geometry mechanism for VB38 17201-0R080 Toyota 2.0L 1AD-FTV 91kW ...

Nozzle ring assy 55515809 55511786 40008694 for Opel 2.0 CDTi 128kW 2020 -

Nozzle ring 54399700057 VOLKSWAGEN TOURAN 1.9 TDI BLS

Nozzle ring 53039700122 AUDI A5 2.0 TDI CAGA

Nozzle ring VV19 Mercedes-PKW Vito 115 CDI W639 OM646

Nozzle ring 799671 AUDI A4 3.0 TDI 245 QUATTRO W36GEN2

Nozzle ring 753392 BMW 530d E60 E61 M57N

Nozzle ring assy BW-06-0028 for 8513635 BMW B47C20 2.0L

Nozzle ring assy for V50VAT-SA012B

VNT nozzle cage GT17-700 for 777159-3 AUDI A3 2.0L TDI 125kW

VNT nozzle cage 783412-0003 057145874J Audi Q7 4.2 TDI CCFC 250kW 2009-2015

Variable geometry for 7794259F 758351-0002 BMW 3.0L M57TU2EU4 170kW 2005-

Turbo Nozzle ring 805713-0004 for Audi 3.0 BiTDI 218KW 2011 059145061L

Nozzle ring assy A6540902400 831120-5 Mercedes 2.0L CDi 654920 142kW 2016-

Nozzle ring 795680 VOLVO V70 2.0D D3

Nozzle ring 813860 VOLKSWAGEN GOLF 1.6 TDi

Nozzle ring 53039700109 AUDI A4 2.0 TDI (B8) CAHA

Nozzle ring 769909 VOLKSWAGEN TOUAREG 3.0L TDI CASA

Nozzle ring 53049700044 AUDI A4 2.7L TDI B7 C6 BSG BPP 180KM

Nozzle ring 53049700032 VOLKSWAGEN T5 Transporter 2.5L TDI AXD

Variable geometry 821866-4 04L253010H VW 2.0TDI CUNA/CUPA 135kW 2013-

Variable geometry 40007575 11658514266 BMW 1.5L B37D15A 70kW/85kW 2015-

Zmienna geometria 845275-1 9813241380 Peugeot 1.5 Blue HDi 94kW 2018-

VNT gasket (turbine) 758353-0007

VNT gasket (turbine) A6280960299

VNT gasket (turbine) 775274-0002

VNT gasket (turbine) 753420-0002

Uszczelka VNT 16359700003

VNT gasket (turbine) 54359700014

VNT gasket (turbine) 16389700016

VNT gasket (turbine) 14411-3XN2A

- 1

- 2

- 3

- 4

- 5

What is variable turbine geometry?

Variable geometry turbocharger (VGT) technology is frequently used in the forced induction systems of internal combustion engines. Its main purpose is to adjust the turbine rotor's geometry to the engine's current operating conditions, with the aim of optimizing the turbocharger's performance. This leads to improved vehicle dynamics and increased fuel efficiency. The turbine core, including the CHRA (Center Hub Rotating Assembly), and the nozzle ring assembly play crucial roles in achieving these objectives. Aluminum alloys, stainless steel, and advanced composites are widely used in manufacturing due to their excellent mechanical and thermal properties.

How does the variable turbo geometry work?

The variable geometry turbine relies on dynamically modifying the geometry of the turbine blades to adjust the exhaust gas flow to variable engine operating conditions. In conjunction with the adjustable blade mechanism, the nozzle ring assembly plays a pivotal role in optimizing the gas energy utilization. Unlike regular turbochargers, the blade geometry remains adjustable, allowing for changes in the shape and angle of the blades. With variable geometry turbine (VGT), the turbine blades are movable and can adjust their position in response to control signals. This feature allows for the adjustment of the gas inlet area of the turbine according to the engine's requirements. The variable geometry blades align to optimize the utilization of gas energy when the engine demands more power. This results in a faster spinning turbine rotor, which delivers more compressed air to the engine, ultimately leading to increased power and improved engine responsiveness.

What are the advantages of variable geometry?

The evolution of turbocharger technology represents a significant leap forward in improving the performance of vehicle engines. One notable solution in this evolution is the implementation of variable turbine blade geometry. Let's look at its main benefits:

- Improved responsiveness: variable turbine blade geometry allows faster response to engine demands, especially during hard acceleration.

- Optimised fuel consumption: achieving optimum fuel consumption is a key benefit, resulting in greater efficiency across a wide range of driving conditions.

- Low-speed torque optimization: In city driving, the main benefit of variable geometry is the optimization of low-range torque, which improves the overall driving experience.

- Even load distribution: the ability to evenly distribute the load contributes to improved engine durability by maintaining a more stable operating mode.

- Nozzle ring enhancement: another critical aspect contributing to the efficiency of turbocharger technology is the nozzle ring assembly. By incorporating advanced designs and materials, the nozzle ring further refines the performance of the turbocharger. It plays a key role in controlling the exhaust gas flow, contributing to better overall turbocharger efficiency and performance.

What is the price of a turbine geometry and how do I do a purchase with a quality guarantee?

Nozzle ring is just one of the many products offered by the Wiatreo online shop, which specializes in the sale of turbochargers and their components. As a representative of the Lithuanian company Turbocentras UAB, Wiatreo ensures access to top quality products. The shop offers competitive prices for variable geometry components, coupled with a quality guarantee - an essential factor when purchasing key components that affect engine performance. The shop guarantees fast and secure delivery throughout Poland. In addition, the secure payment options offer convenience and confidence in online transactions. If you're looking for competitively priced variable geometry for your turbocharger, backed by a quality guarantee and the assurance of fast delivery, Wiatreo is an excellent choice.