Turbocharger Shaft & Wheel

Shaft and wheel for 701470-0001

Shaft and wheel for 819976 BMW 520d 2.0L 140kW SW-819976

Shaft and wheel for 781504-0001

Shaft and wheel for 813860-0001

Shaft and wheel for 802718-0004

Shaft&wheel for 53269706419

Shaft and wheel for 49135-05610

Shaft and wheel for 764381-0001

Shaft&wheel for turbo 05L253019F / 05L253019J / 05L253019B

Shaft and wheel for 10009700072

Shaft and wheel for 756867-0001

Shaft and wheel for VA430072

Shaft and wheel for 736168-0002

Shaft and wheel for 54399700006

Shaft and wheel for 3584122

Shaft and wheel for 766924-0001

Shaft&wheel for 793996-0001

Shaft and wheel for 3537902001

Shaft and wheel for 452213-0001

Shaft and wheel for 10009700023

Shaft and wheel for 454061-0001

Shaft and wheel for 758351-0002

Shaft and wheel for 757608-0001

Shaft&wheel for 12709700217

Shaft and wheel for 54399700005

Shaft and wheel for 701196-0001

Shaft and wheel for 757779-0004

Shaft&wheel for 10009700198

Shaft and wheel for 10009401085

Shaft and wheel for 10009700055

Shaft and wheel for GA-02-0008

Shaft and wheel for 54409700001

Shaft and wheel for 740821-0001

Shaft and wheel for 178108

Shaft and wheel for 3768586

Shaft and wheel for 721875-0001

Shaft and wheel for 54359700005

Shaft and wheel for 53049700033

Shaft and wheel for 757886-0001

Shaft&wheel for 847009-0006

Shaft&wheel for 53049700024

Shaft and wheel for 10009700143

Shaft&wheel for 825759-5002S

Shaft and wheel for 717478-0001

Shaft&wheel for 709050-0003

Shaft and wheel for 452204-0001

Shaft and wheel for 704442-0001

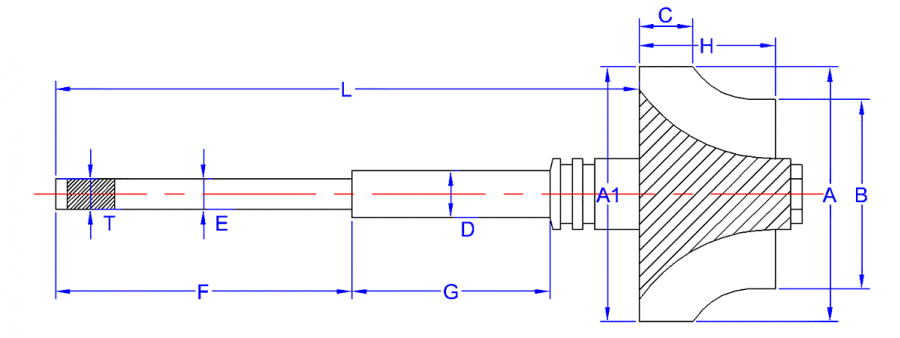

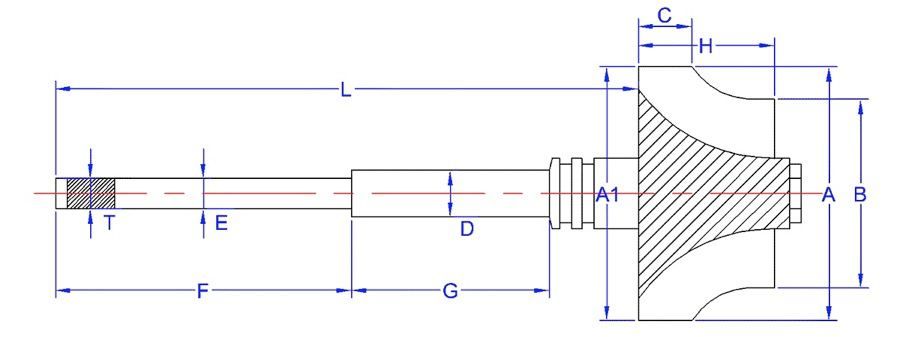

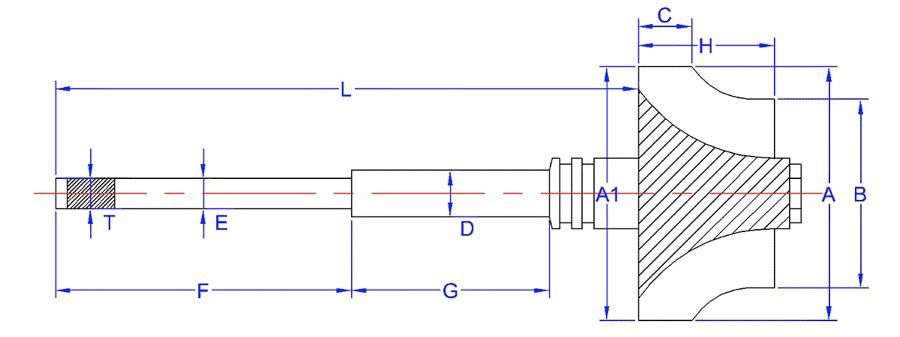

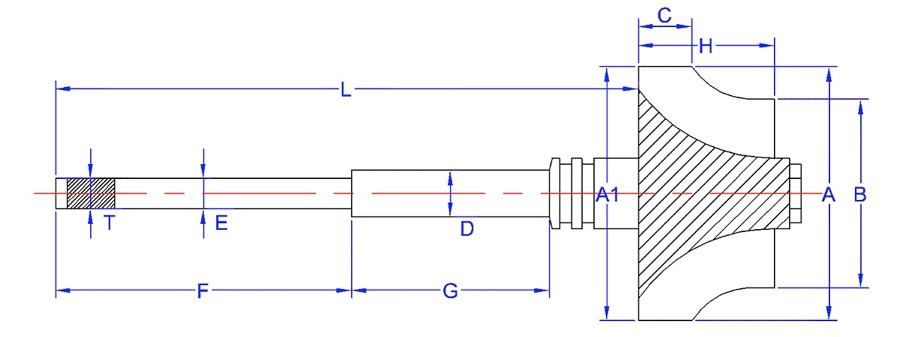

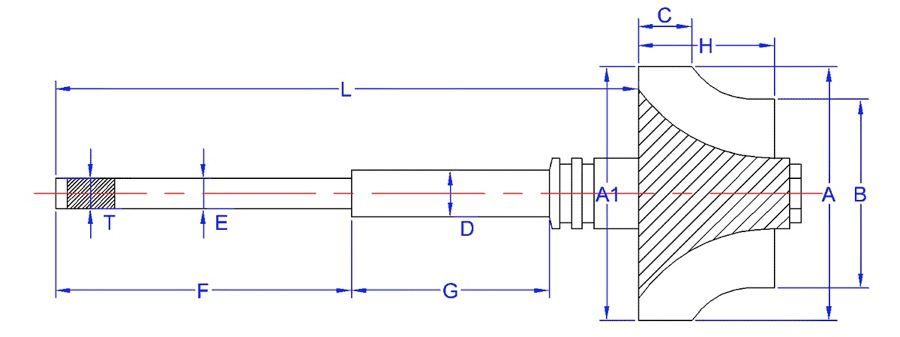

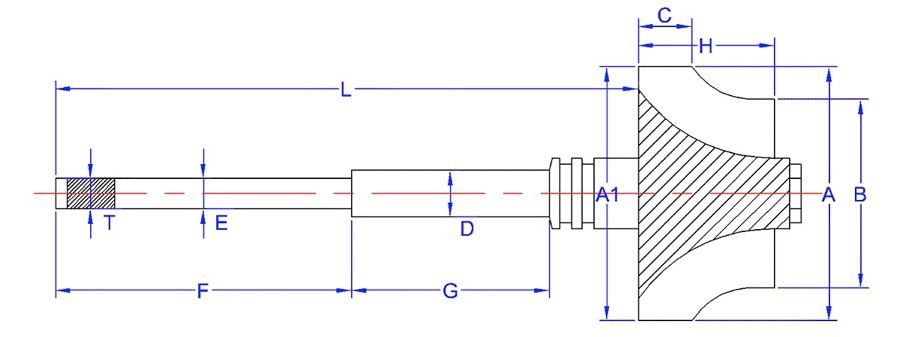

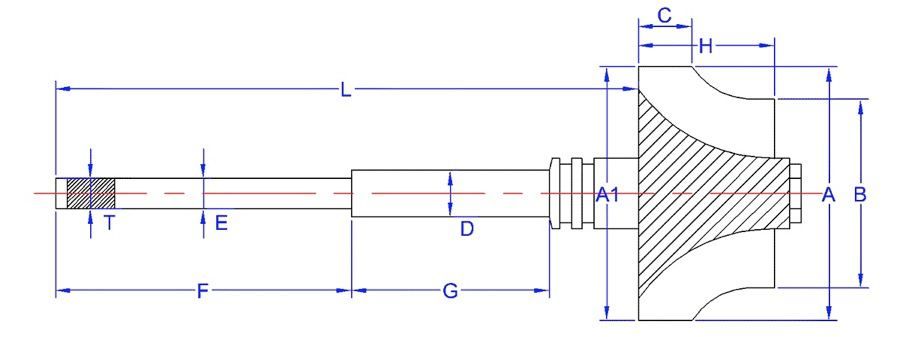

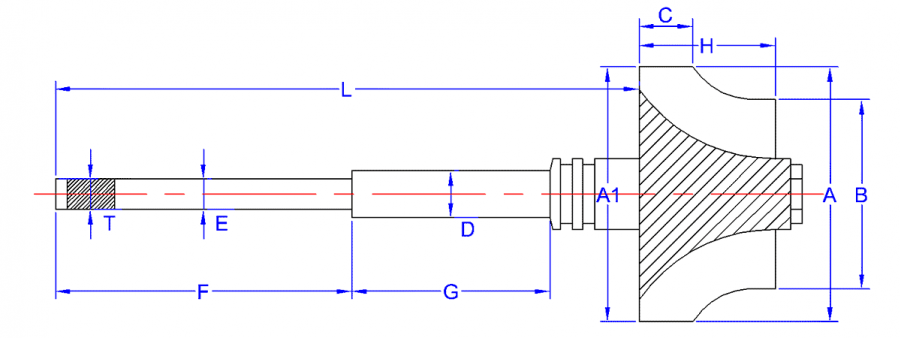

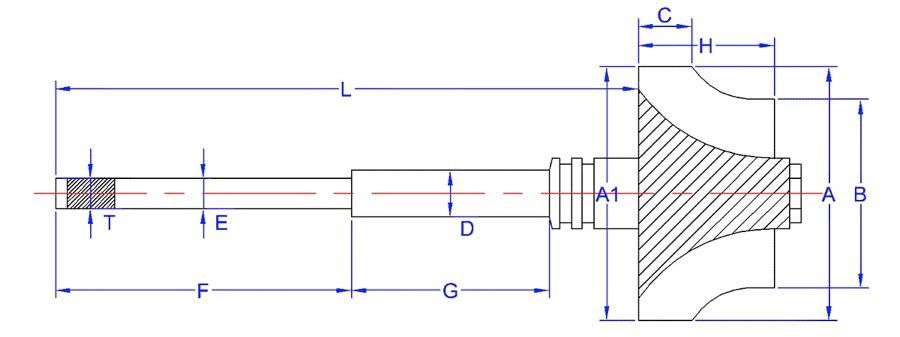

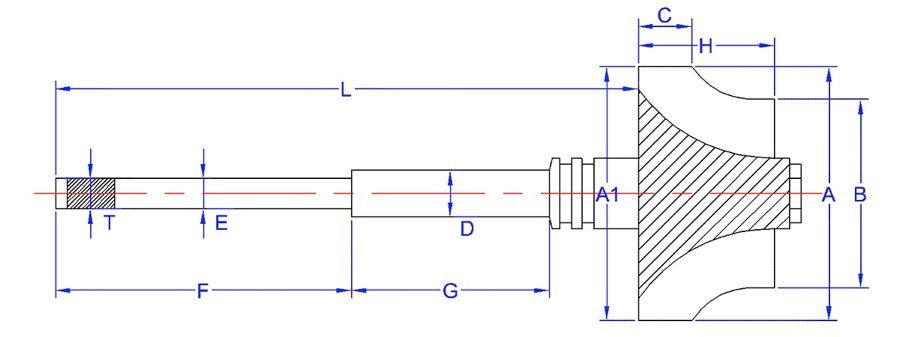

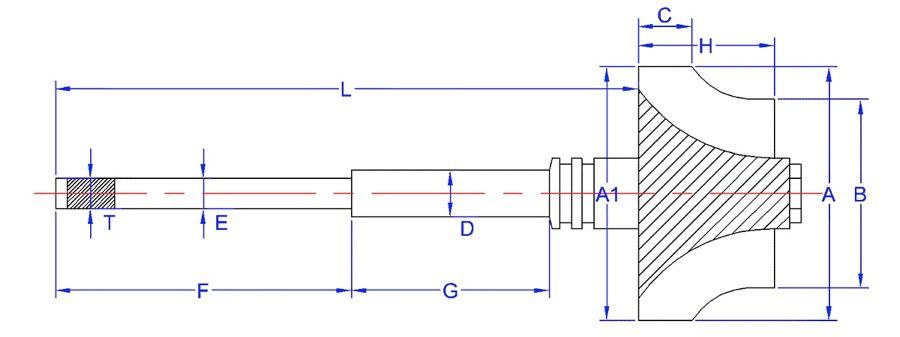

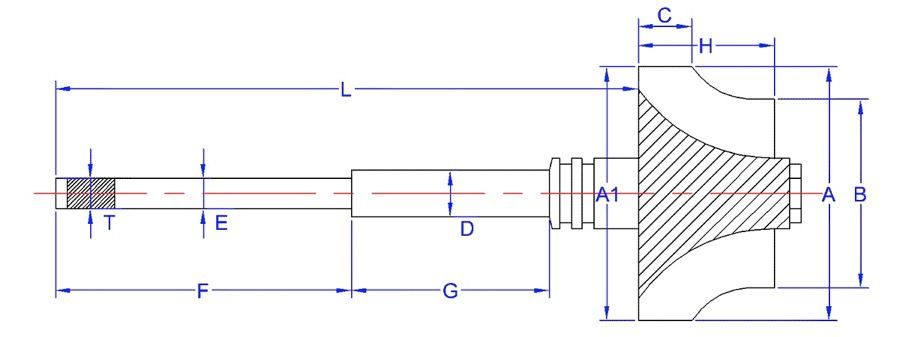

- 1

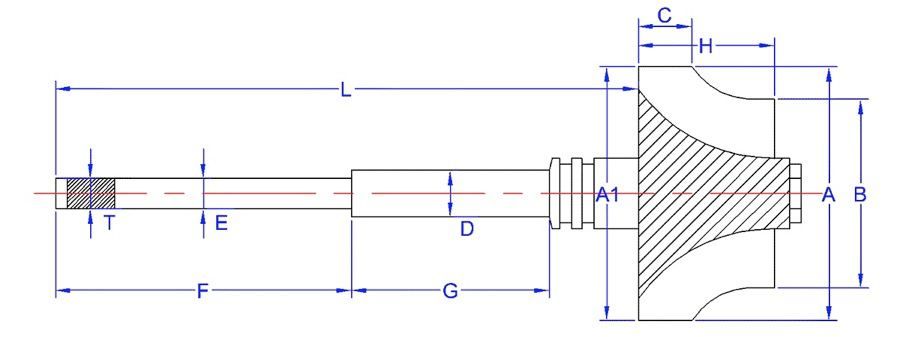

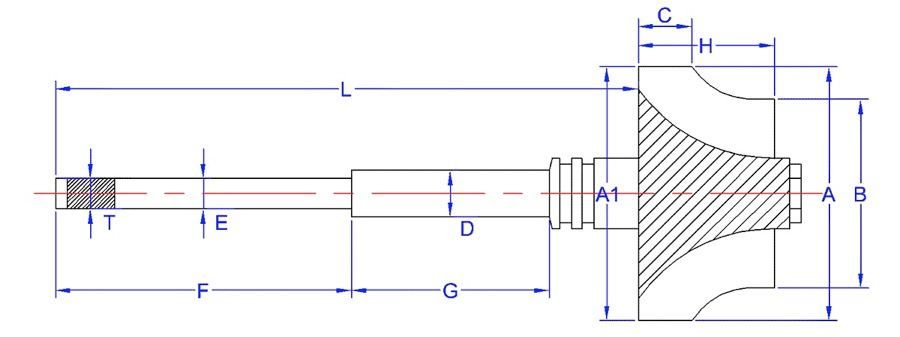

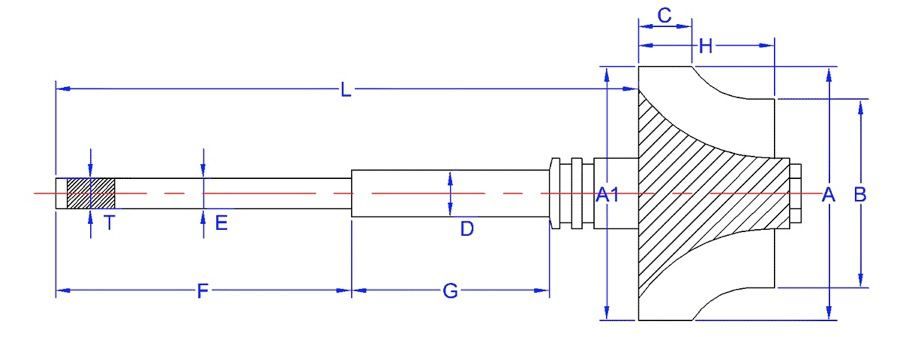

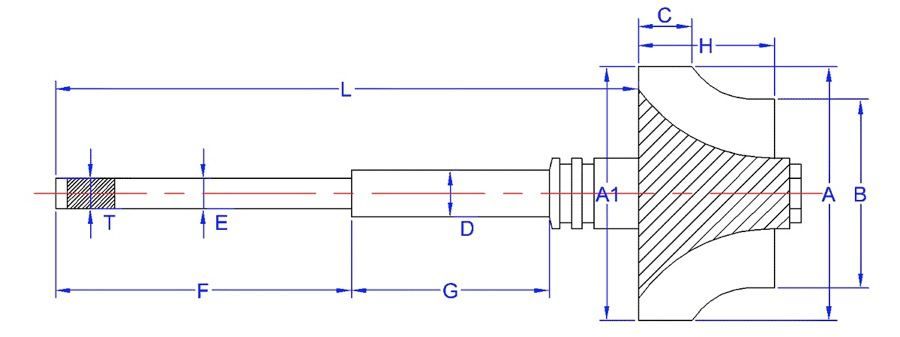

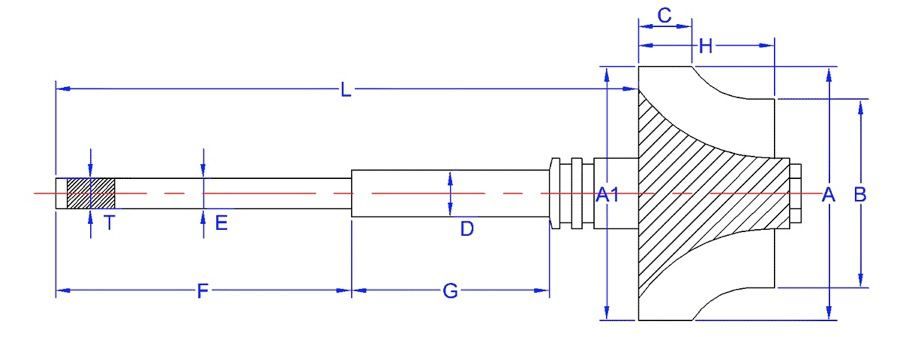

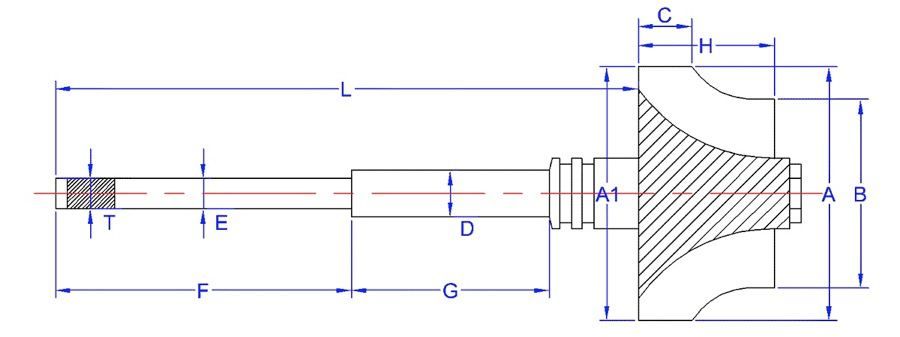

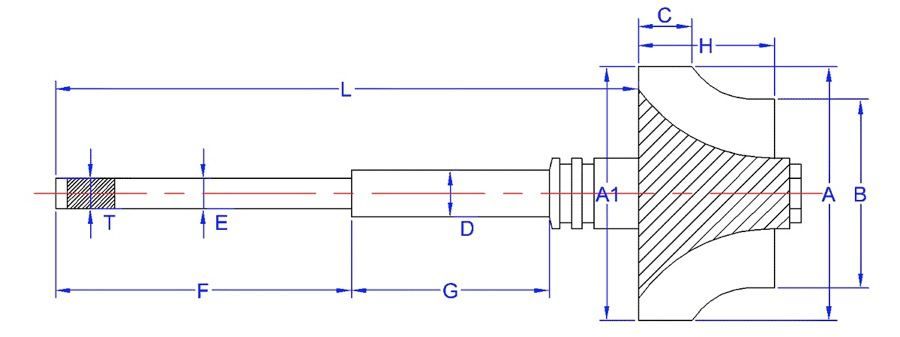

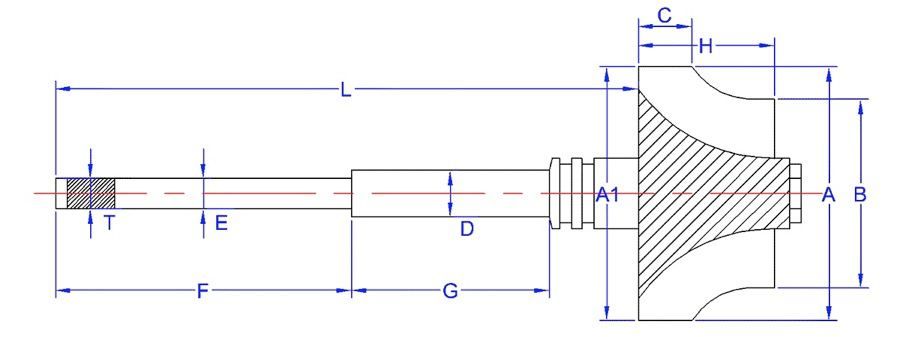

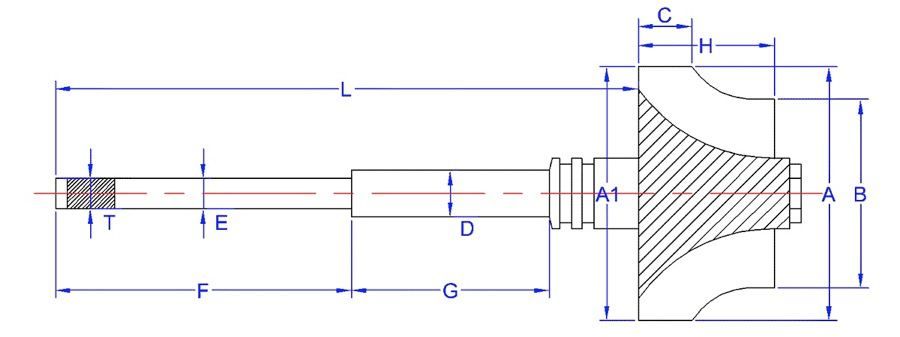

- 2

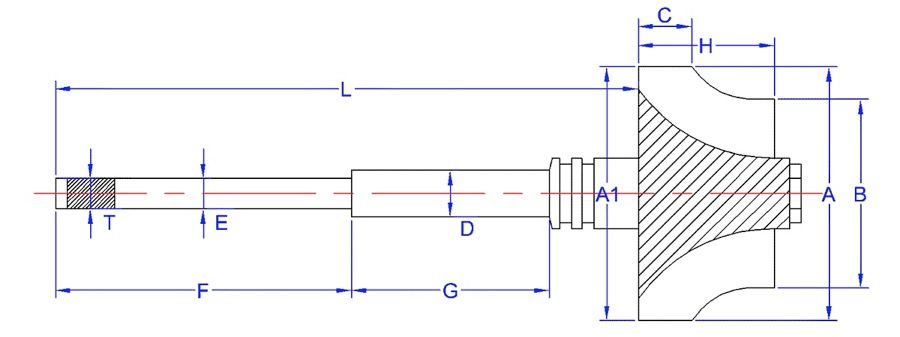

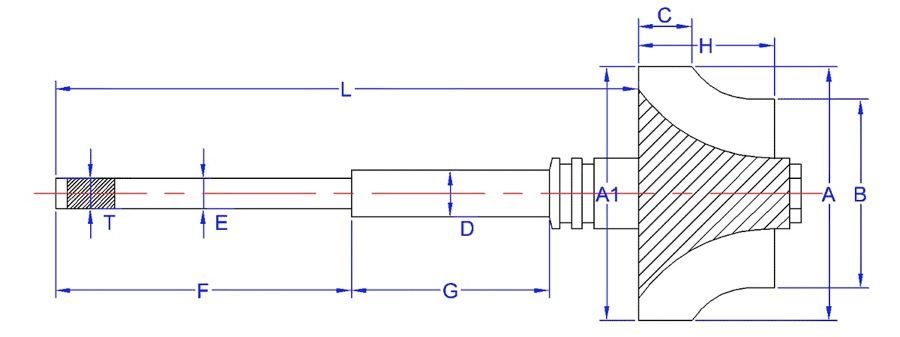

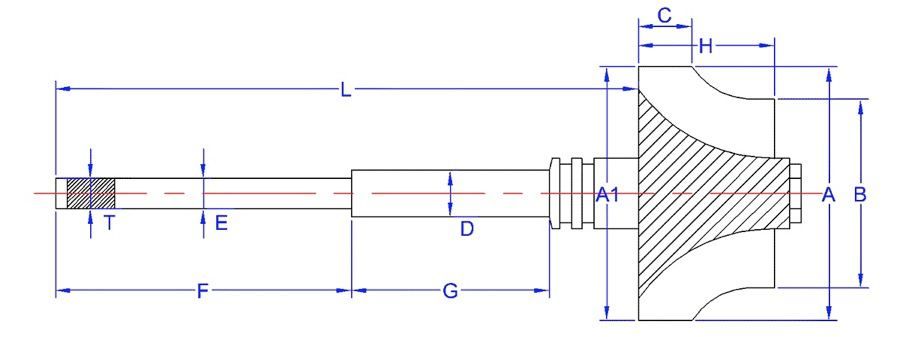

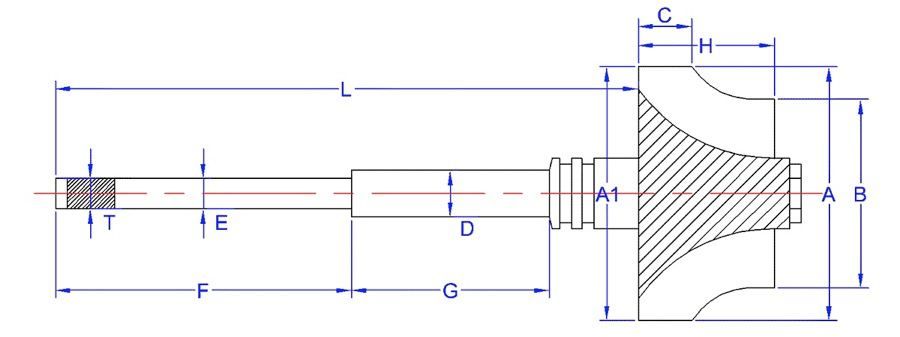

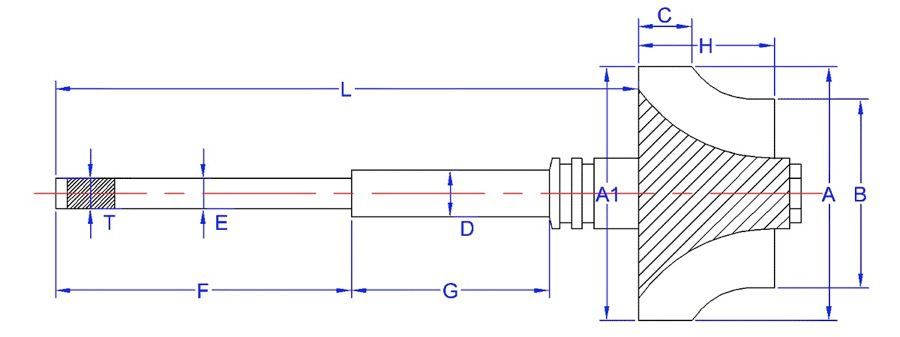

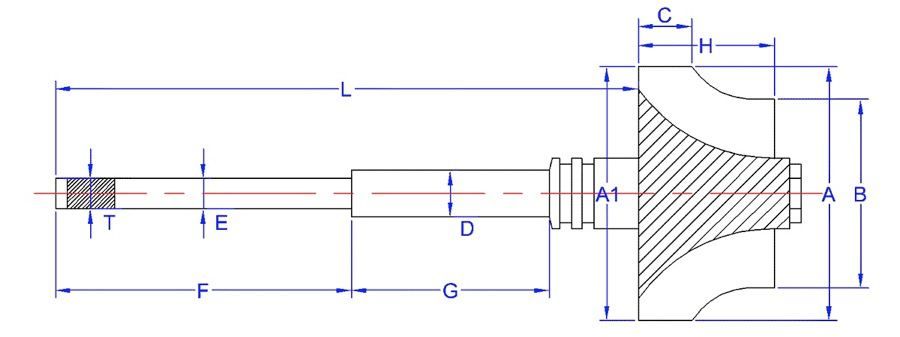

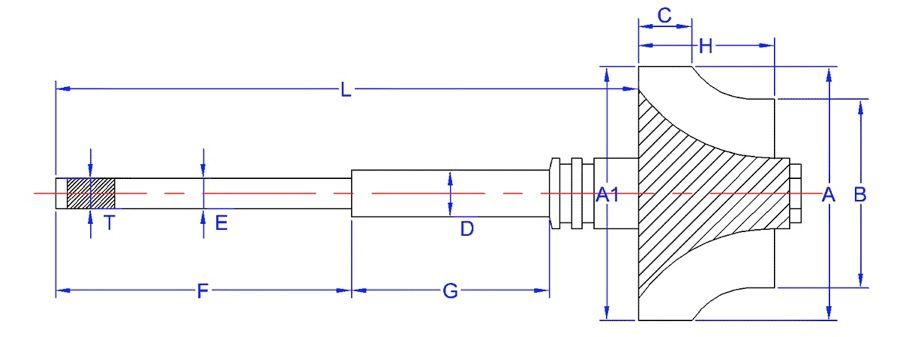

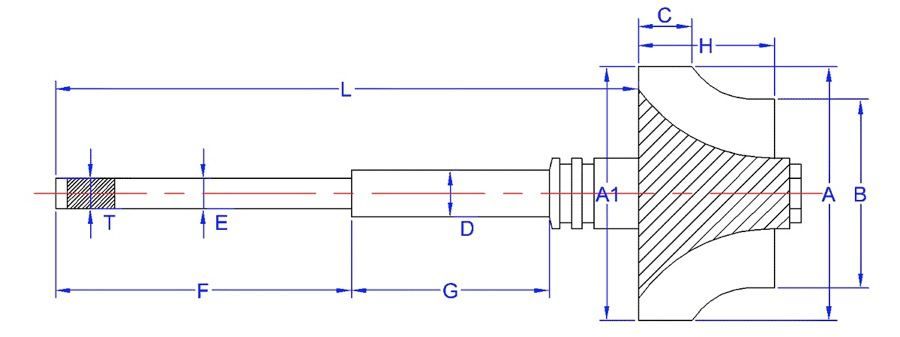

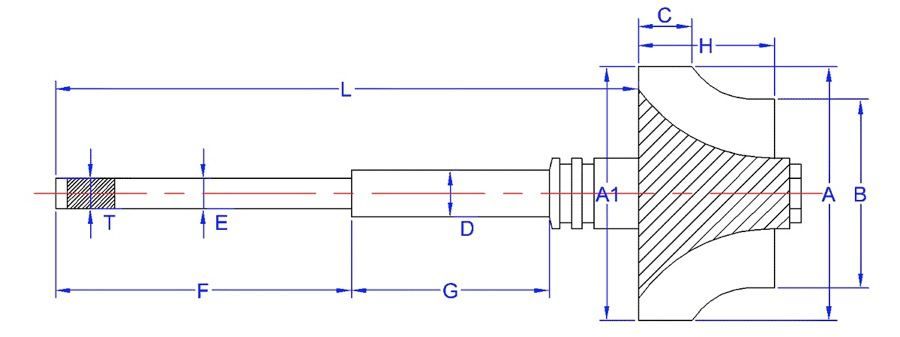

- 3

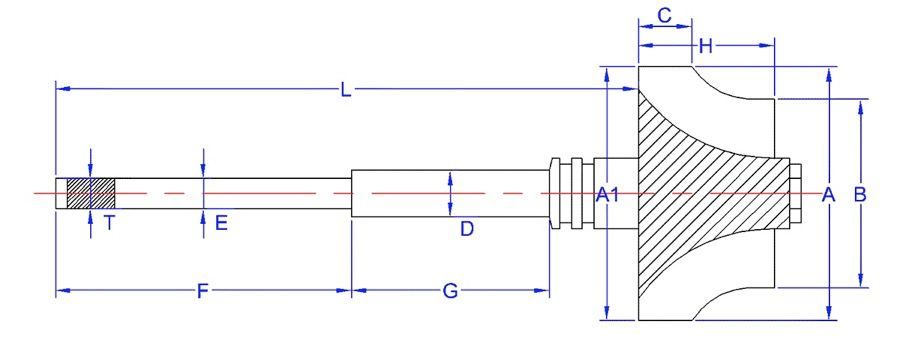

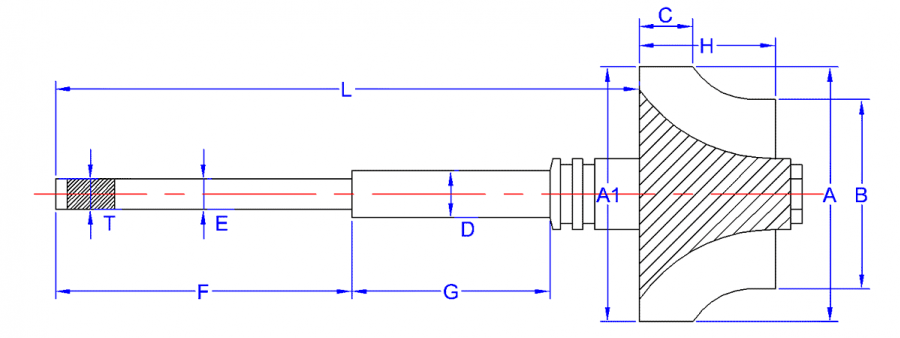

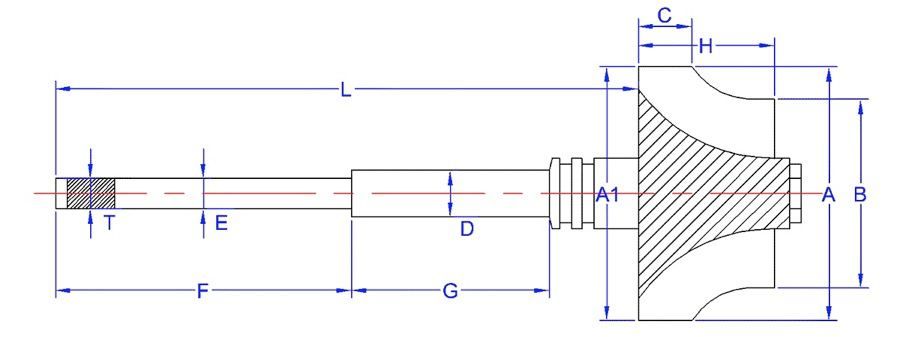

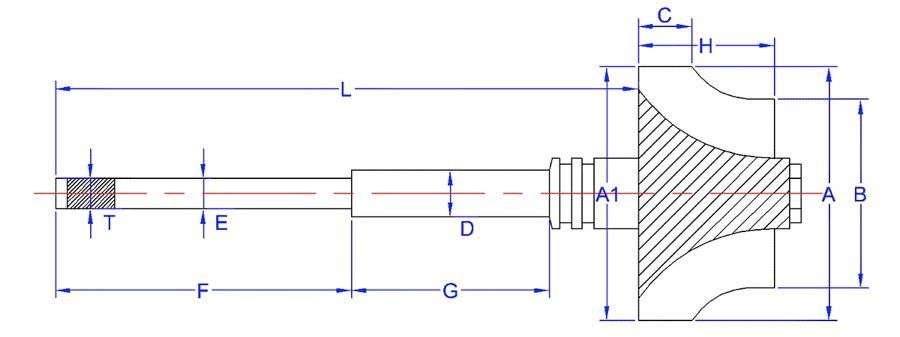

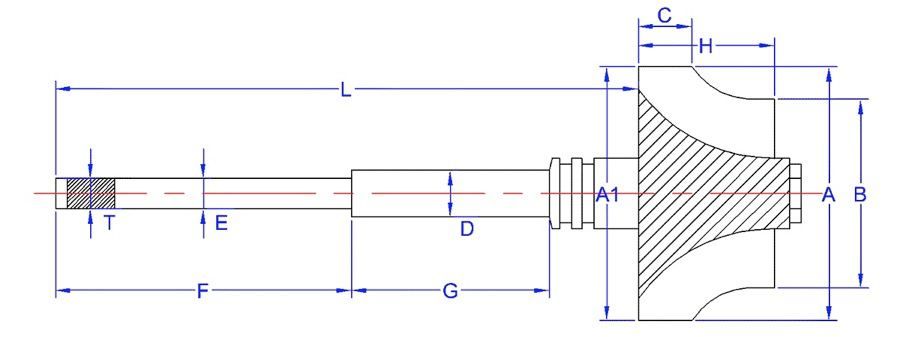

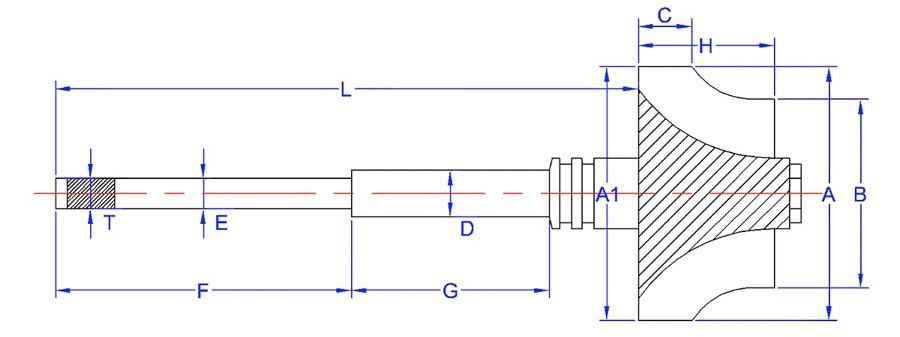

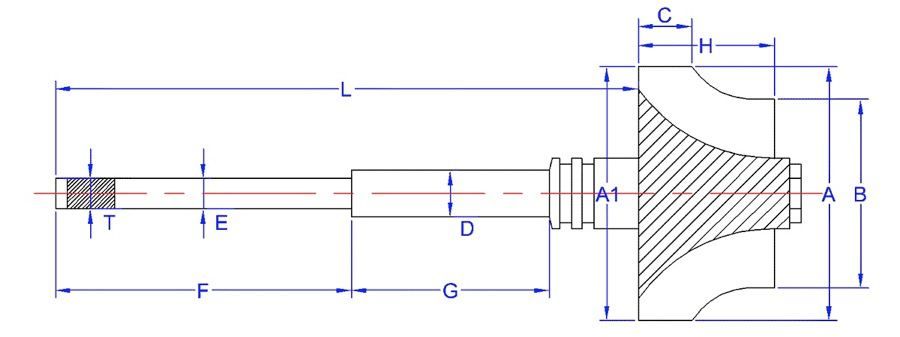

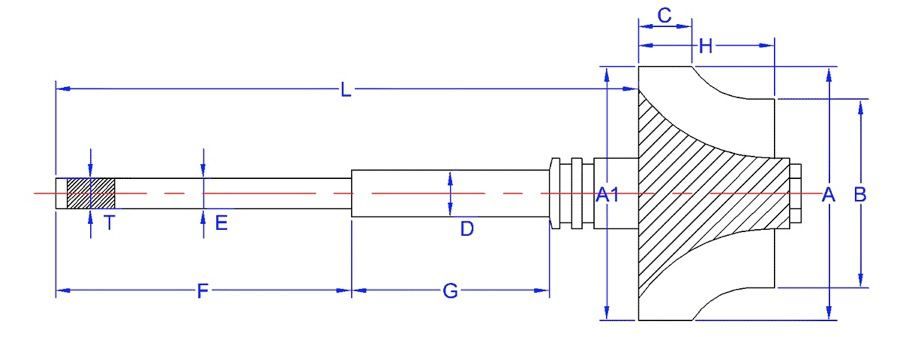

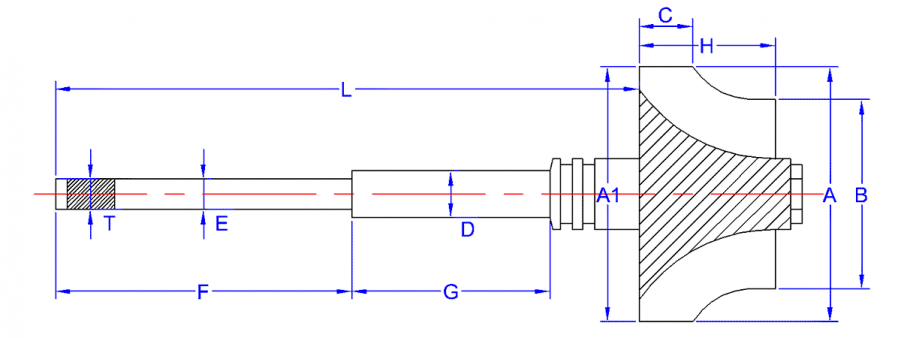

- 4

- 8

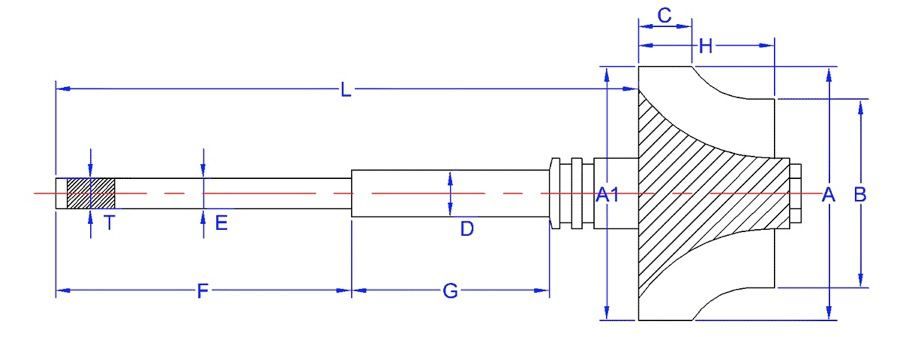

What is the turbine rotor?

It is an important component of the turbocharger system. The turbocharger shaft, on which the compression wheel is located, converts the kinetic energy of exhaust gases into rotational mechanical energy. This process occurs because centrifugal forces act on the working blades attached to the crown of the rotor during rotation.

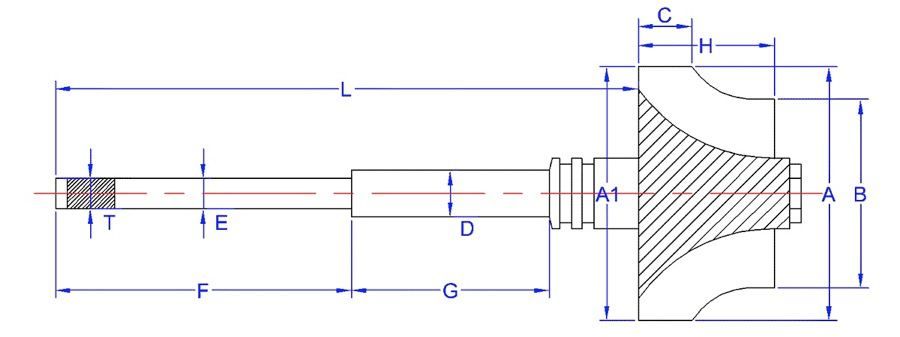

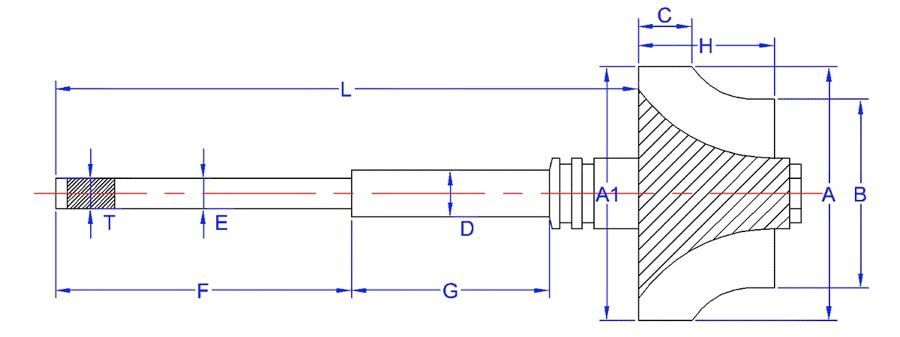

A characteristic feature of the turbocharger shaft is its complex structure, which includes:

- Central shaft;

- Crowns with blades.

Blades attached to the crown play a crucial role in energy conversion, creating circumferential forces that precisely direct the flow of exhaust gases. The turbocharger rotor needs to be made of materials with high strength and resistance to high temperatures, as this ensures its ability to withstand destructive centrifugal forces. This requirement is crucial for ensuring the durability and reliability of the turbine as a whole.

Why does the turbocharger rotor fail over time?

Due to intensive use, the turbocharger shaft can undergo significant wear, especially when operating at high speeds, often exceeding 250,000 revolutions per minute. The main causes of turbine rotor damage are the wear of sealing rings and bearings, leading to friction of the rotor blades against the turbine housing and shaft bearings. As a result, the turbine rotor may deform or even break, disrupting the normal operation of the turbocharger. Repairing these components is usually cheaper than replacing them with a new element, so it is important to quickly diagnose and address any malfunctions.

It is recommended to carry out repairs at an early stage of rotor wear to prevent destruction and maintain optimal turbocharger performance.

Features of turbocharger rotors in the Wiatreo online store assortment

A key factor in the production of turbine rotors is the choice of material, which depends on the system's operating temperature. This indicator varies significantly depending on the type of engine - diesel or gasoline - and the type of vehicle - passenger car or truck. Special metal alloys resistant to high temperatures, vibrations, and pressure are used to produce various types of rotors.

Among the materials used for rotor production are:

- Nickel and chrome alloys. They are effective for operating at temperatures above 1000°C, suitable for high-temperature conditions of gasoline engines.

- Gray iron. Less commonly used due to temperature limitations up to 680°C.

- Heat-resistant austenitic steel. Designed for conditions with maximum temperatures of gasoline engines.

The Wiatreo online store is an official distributor of the Lithuanian manufacturer TURBOCENTRAS UAB, specializing in the sale of high-quality turbocharger rotors. We offer durable replacement rotors for turbochargers that perfectly match the quality and dimensions of the originals but at more attractive prices. Our catalogue includes turbocharger shafts for various car brands, including BMW, Toyota, Mitsubishi, and others. Each rotor is characterised by a different number of blades and their type, rotation type, and the number of sealing rings. For the convenience of customers, the rotor description includes compatibility with specific turbocharger models.

To purchase turbine rotors, contact Wiatreo representatives using the phone numbers provided on the website. In case of insufficient information in the description, we will help you make the right choice.