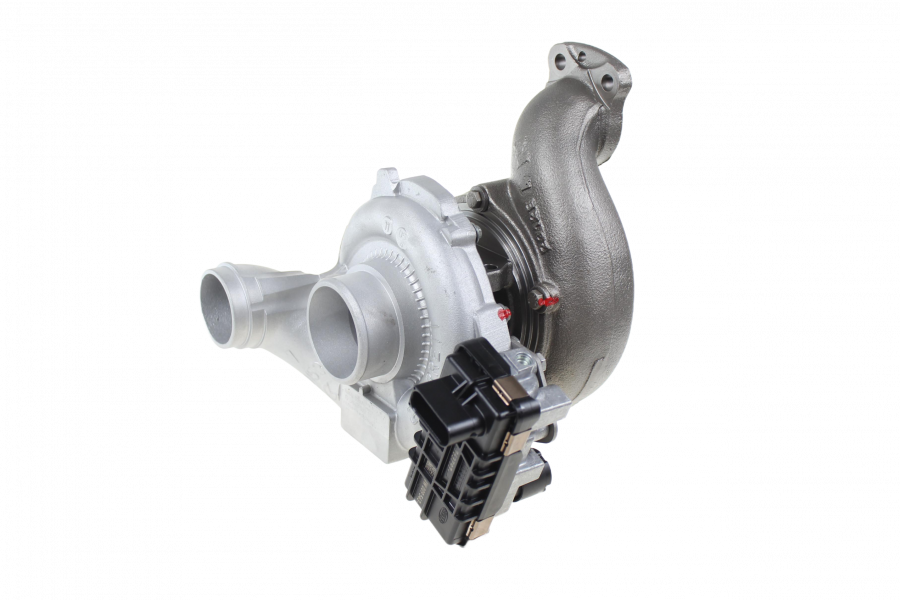

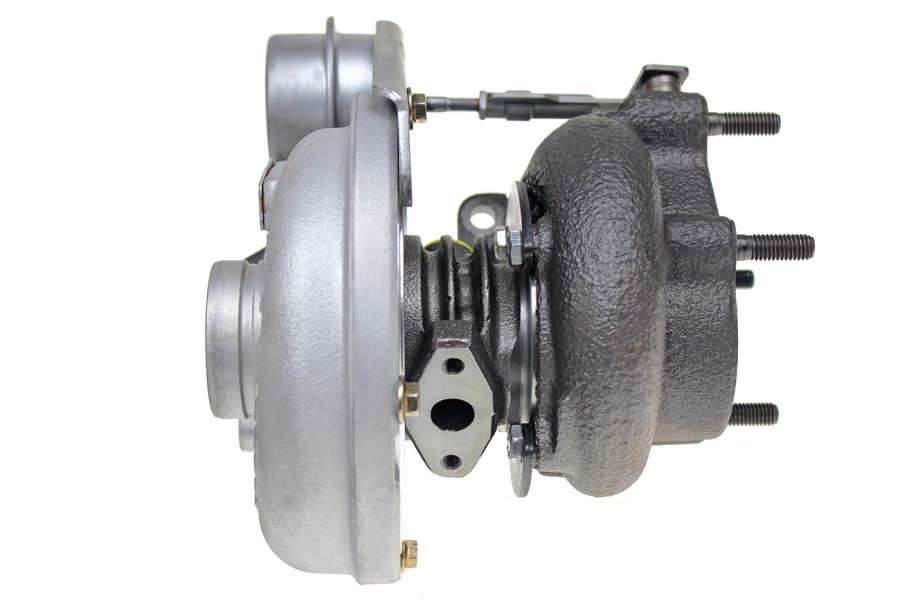

REMANUFACTURED TURBOCHARGER 454061-5001RS

Manufacturer:

Garrett Motion

SKU:

454061-1RS

Serial number:

454061-5001RS

Main number:

45406 -1 RS

About product

REMANUFACTURED TURBOCHARGER

Turbo number: 454061-5001RS

Garantee: 12 months

Deposit: Proce includes deposit. While old turbo return, client receives 200 zł deposit.

Brand: Turbocentras UAB

Alternative turbocharger numbers:

- 454061-0008 454061-5008s 454061-8

- 454061-0010 454061-5010s 454061-10

- 454061-0014 454061-5014s 454061-14

- 7711135840

- 7701044612

- 5001859132

- 500385898

- 99466793

- 93184040

- 4500939

- 9161239

- 860077

Cars:

- FIAT DUCATO 2.8 8140.43.2600 102KM/75KW OD 1998

- IVECO DAILY 2.8 8140.43.2600 102KM/75KW OD 1998

- RENAULT MASTER X/70 2.8 8140.43.2600 115KM/85KW OD 1998

- RENAULTMASTER T28 2.8 DTi S9W700 114KM/84KW 1998-2002

- RENAULT MASTER T33 2.8 DTi S9W700 114KM/84KW 1998-2001

- RENAULT MASTER T35 2.8 DTi S9W700 114KM/84KW 1998-200

- RENAULT MASTER T39 2.8 DTi S9W700 114KM/84KW 1998-2002

TURBOCHARGER REGENERATION PROCESS:

Repairing a turbocharger is a complicated and time-consuming process carried out by highly qualified personnel using technically advanced machines.

The regeneration process at Turbocentras consists of the following stages:

1. Disassembly of the turbine into individual parts

2. Ultrasonic cleaning of dismantled turbine parts

3. Automatic sandblasting of aluminum and cast iron housing

4. Installation and balancing of the center of the turbocharger (we use parts of our own production)

5. Installing the cartridge in the turbine and setting the nozzle ring / wastegate valve

6. Replacing the moving parts of the controller (only applies to turbine models with electrical control)

All works are carried out using high-class machines:

Balancer - TurboTechnics VSR400

Nozzle Ring setting - Turboclinic VNT Analyser

Controller repair – Deltatech VNTT-PRO, G3 REA-MASTER

WHY IS IT WORTH TO CHOOSE TURBOCHARGER REGENERATED BY TURBOCentras UAB

1. We use only new parts for the regeneration of turbochargers (cartridge, variable geometry)

2. After the repair, the turbochargers undergo an air flow adjustment test on two independent machines in order to compare the parameters

3. The regenerated turbine is mechanically checked for oil permeability

4. All electronic controllers are repaired or replaced with new ones

5. Cracked cast iron parts are replaced with new ones (not welded)

PLEASE CHECK THE NUMBERS FROM THE TURBO NAMEPLATE BEFORE PURCHASING!