GEOBOOST-7000 - Dynamic-static machine for geometry calibration and turbine performance evaluation

Manufacturer:

VTM Group

SKU:

GEOBOOST-7000

Serial number:

GEOBOOST-7000

Main number:

GEOBOOST-7000

About product

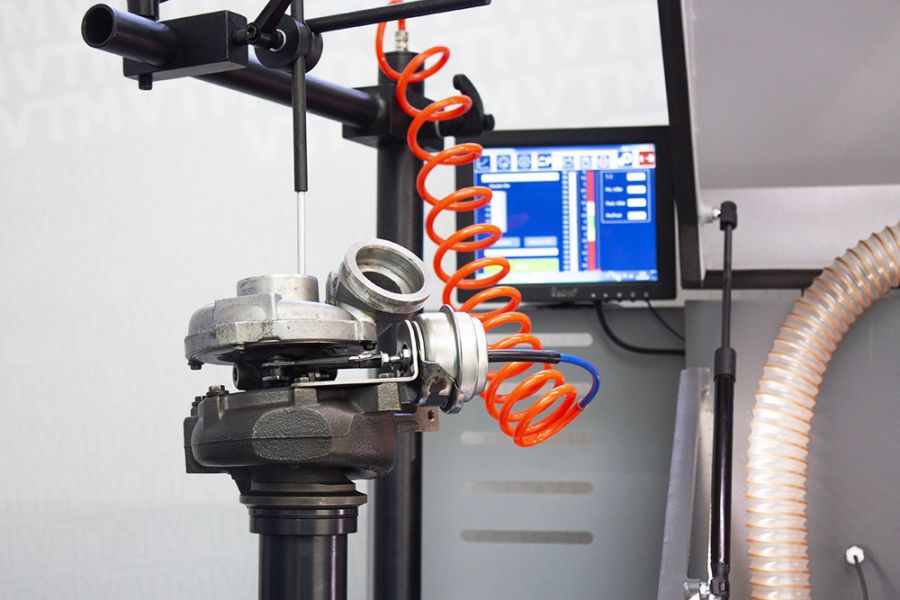

GeoBoost-7000 – Advanced Machine for Static and Dynamic Turbocharger Calibration

GeoBoost-7000 is a modern, dual-zone diagnostic station that combines static variable geometry calibration functions with dynamic turbocharger testing under near-real conditions. This device enables comprehensive assessment of turbocharger condition after repair, as well as during tuning or modernization.

Functions and Capabilities of GeoBoost-7000:

1. Static Geometry Calibration:

- Universal Mounting System: Enables installation of turbochargers using magnetic adapters or clamps, allowing work with a wide range of models, including those made from non-magnetic materials.

- Adjustment of Extreme Vane Positions: Eliminates the "blow-through" effect, protecting the engine and turbocharger from damage.

- Actuator Spring Diagnostics: Enables assessment of the actuator spring condition, allowing early detection of potential problems and increasing turbocharger reliability.

- N75 Valve Test: Allows checking the operation of the N75 valve, facilitating fault analysis and reducing repair time.

- High-performance Vacuum Pump: Provides the necessary vacuum and airflow through the turbocharger, enabling comprehensive diagnostics and tuning under conditions close to real-world operation.

2. Dynamic Diagnostics and Testing:

- Tests Under Near-Real Conditions: Enable accurate monitoring of turbocharger condition and performance, including oil leak tests.

- Dedicated Software with Advanced Algorithms: Allows precise determination of turbocharger operating parameters after tests, simplifying analysis and improving diagnostics.

- Real-time Data Display: All operations and turbocharger operating parameters are displayed in real-time in graphical-digital format, giving technicians immediate access to key information.

- Automatic Graph Creation and Analysis: Automatic creation of pressure-to-flow graphs at the turbocharger inlet and outlet allows for qualitative diagnosis of turbine component conditions and comparison of current results with reference data and previous tests.

- Extensive and Expandable Test Plan Database: Availability of a database covering over 2,000 test plans, which can be expanded, allows work with a wide range of turbochargers and their analogs, ensuring versatility and adaptability of the station.

- Compatibility with ATP-1000: Integration with the ATP-1000 tester enables diagnostics of turbochargers with electronic actuators and testing of electric actuator servomechanisms, extending the inspection and maintenance capabilities for modern turbochargers.

| Maximum compressor wheel diameter: | 80 mm |

| Maximum rotor speed: | up to 300,000 rpm |

| Required pressure in pneumatic system: | 0.8 – 1.0 MPa |

| Recommended minimum air tank capacity: | 1.0 m³ |

| Device dimensions (L × W × H): | 780 × 1450 × 1274 mm |

| Device weight: | approximately 285 kg |

| Power supply: | 380 V ±10%, 3 phase, 50 Hz ±1 |

| Power consumption: | not less than 1.5 kW |

| Balancing system: | Boost Test |

Prerequisites for Starting Work:

- Vacuum Pump: (if not integrated with the device – must provide sufficient airflow for dynamic tests and calibration)

- Level Installation Surface: Standard hard workshop floor, without the need for special foundations.

Application and Benefits of Implementing GeoBoost-7000:

GeoBoost-7000 is an excellent solution for workshops specializing in regeneration, tuning, and comprehensive diagnostics of variable geometry turbochargers (VNT/VGT), as well as for facilities producing or modernizing charging systems. The combination of precise static calibration with dynamic load testing makes it one of the most versatile and effective tools on the market.

The device significantly reduces the time needed for turbocharger analysis and calibration, while ensuring repeatability of results, high measurement accuracy, and support for quality processes in modern turbo services.

⏳Delivery time of machine equals 2-3 months from the time of purchase confirmation.

💵The cost of shipping the machine to your location is included in the price!