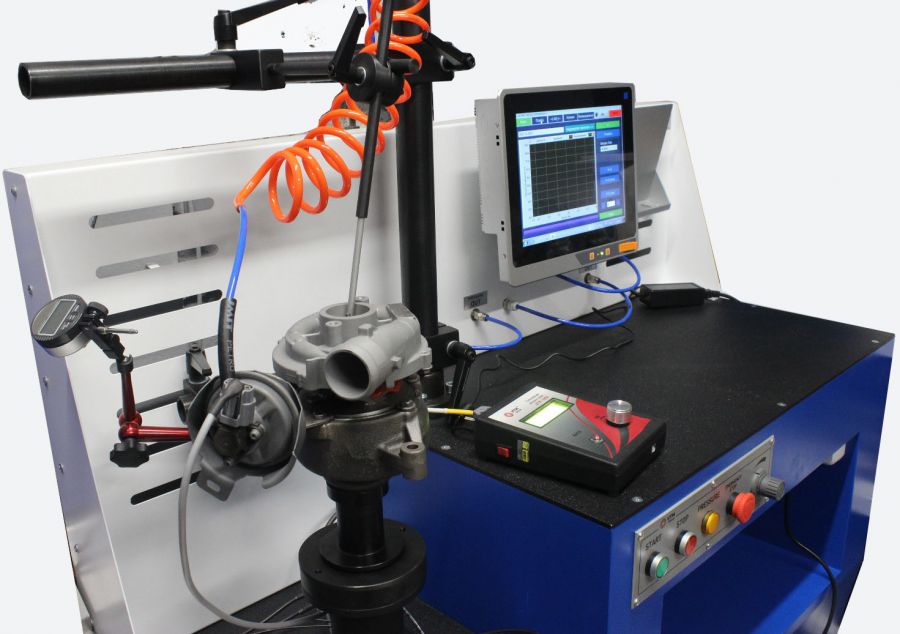

GEOMET-2000 – Static Machine for Adjusting Variable Geometry of Turbochargers

Manufacturer:

VTM Group

SKU:

GEOMET-2000

Serial number:

GEOMET-2000

Main number:

GEOMET-2000, VTM, Statyczna maszyna

About product

Professional equipment for static calibration of variable geometry turbochargers of VNT/VGT type. GEOMET-2000 - a static machine for setting the position of variable geometry in VNT/VGT type turbochargers, with an easy-to-use station that allows for quick installation of the turbine and easy adjustment of the locking screw. A station that allows checking the turbine airflow in LIVE mode, and adjusting the position of the variable geometry during the test, which optimizes the time to process 1 turbine. The machine is controlled by a built-in computer, which is a touch control panel.

GEOMET-2000 - a device that allows for:

- quick and convenient turbine installation

- work without the need to rotate the turbocharger in order to adjust the position of the variable geometry

- ability to check the wear and clearance of the variable geometry pinion through the Δ/Q test.

- N75 valve test, which allows for its verification and more precise adjustment of the turbocharger's variable geometry position.

- handling turbochargers with vacuum actuator

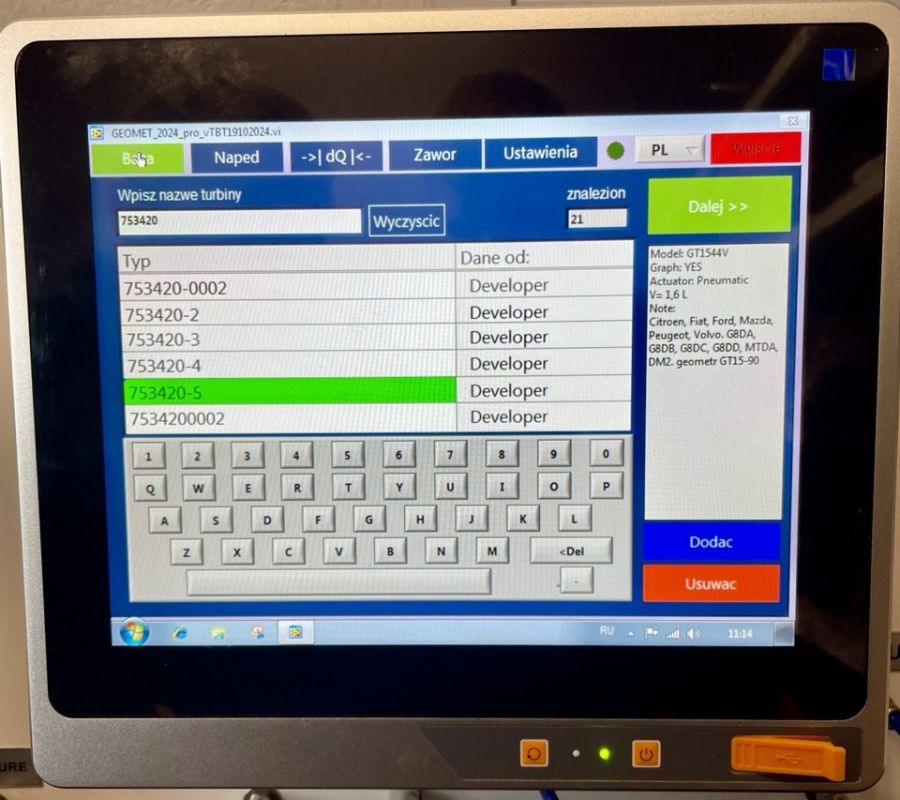

- access to a database of over 2200 turbocharger models, which is continuously updated

- environmental calibration: Takes into account ambient conditions during operation, minimizing measurement errors

- handling various types of turbochargers with variable geometry, including VNT, VGT, VTG, VATN, and VVT;

- adjustment of valve rod length.

| Recommended operating pressure in pneumatic installation: | from 0.6 to 0.8 MPa |

| Maximum vacuum pump capacity: | 180 m³/h |

| Device dimensions (length × width × height): | 1190 × 520 × 1730 mm |

| Power supply: | 220 V ±10%, 1 phase, 50 Hz ±1 |

| Maximum power consumption: | up to 1.5 kW |

| Control software used: | Test Turbo |

| Approximate device weight: | approx. 250 kg |

To start operation, the following are required:

- Compressor min. 50 L (6–8 bar)

- Power supply - 220 V

- Vacuum pump (if not integrated)

- Even workshop surface

NOTE!!! The machine does not have an electronic actuator tester! The GEOMET-2000 machine requires the ATP-1000 tester, created by the manufacturer of this machine. Benefits for users of this machine Setting the turbine geometry on the GEOMET-2000 station leads to:

- Reducing turbine service costs by optimizing the time spent on processing 1 turbine

- Improving the final quality of repairs

- Minimizing the probability of complaints

- Strengthening the workshop's reputation

⏳Delivery time of machine equals 2-3 months from the time of purchase confirmation.

💵The cost of shipping the machine to your location is included in the price!